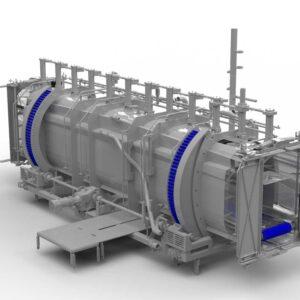

Complete Automated Cheese Processing & Thermal Systems

Our custom systems are tested and tailored to eliminate waste and increase profit. Innovative components create a one-of-a-kind solution in our state-of-the-art facility. Our proven equipment ensures that our systems will position you ahead of the competition for decades to come.

To ensure that every cheese line or complete process exactly meets the needs and market requirements, each machine is tailor-made. This provides the basis for the production of high-quality products. Experienced cheese masters rely on the all-around service of Loos Machine & Automation for plant and process planning, design of lines or entire plants, and automated solutions.

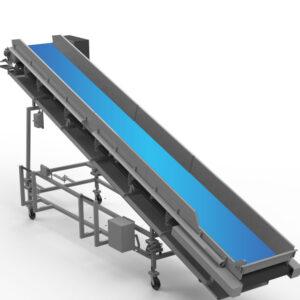

Complementary Equipment

- Platforms

- Automation & Controls (Recipe Integration)

- Overhead Hoist with Barrel & Block Clamping Systems

- Robotics & Pick/Place Options (Palletizing/ Depalletizing/Product Handling)

- Automated Metered Ingredient Delivery to Cookers (Dry or Wet)

- Turn-key Process Piping

- Automated Component Washers & CIP Skids

Your partner for automating with innovation

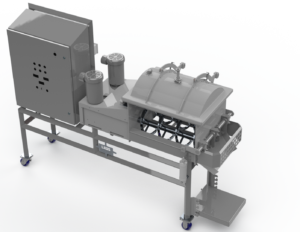

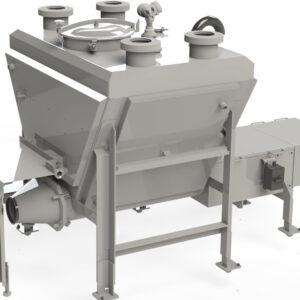

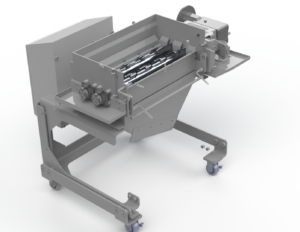

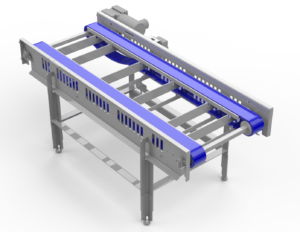

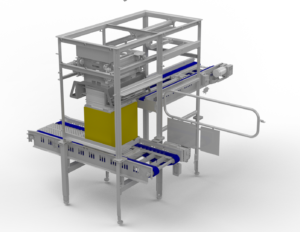

Complete Automated Shred, Crumble, Dice and Cube Systems

Loos Machine & Automation offers a variety of equipment styles for assisting in product reduction of whole loaves, blocks, and wheels for all production levels. Each equipment style is capable of simultaneously mixing and blending various product types if desired.

With reduced operator assistance needed, a complete solution offering will help with cost savings for the present and future. Intuitive controls excel functionality and preciseness to meet your shred, crumble, dice, and cube needs.

We make shred, dice, cube and crumble systems easy to integrate into your new or existing facility.

Questions or Comments?

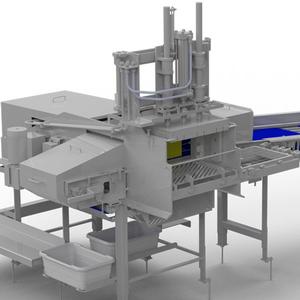

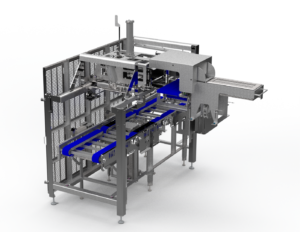

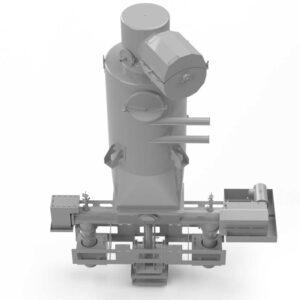

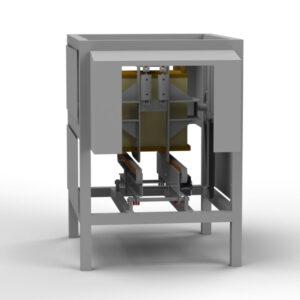

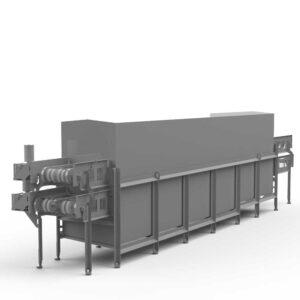

Complete Automated 640 Block & Barrel Systems

Our industry-leading technology allows us to produce the most innovative barrel and block systems for today's world-class cheese manufacturers.

With proven and reliable results to create your custom solution, we guarantee success for years to come. With extensive knowledge in producing 640 lb. block and 500 lb. barrel systems, we offer an abundance of options for a sanitary and complete offering.

Custom Automated Equipment

- 40 lb. or 57 lb. Block Collators

- Autobanding of 640 Blocks (Semi-Auto Banding Also Offered)

- Automated 180° Inverters (Blocks & Barrels; Height Easily Adjusted)

- Automated Barrel Palletizer

- Automated Box Placer to Accept Base Pan

- Automated Funnel & Base Pan Pick/Place Units

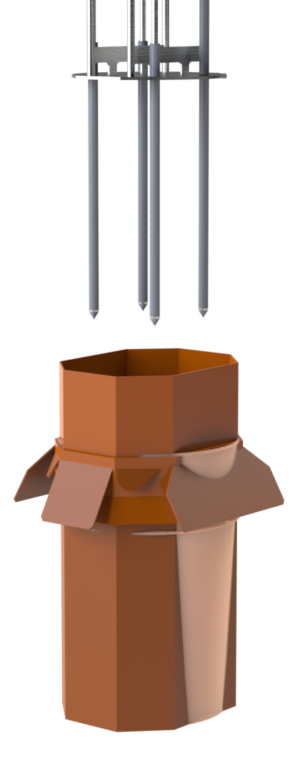

- Automated Funnel Pick/Place (Funnels Designed to Eliminate Use of Loose Angles)

- Automated Natamycin Spraying Stations

- Automated Press Plate Denester (for Barrel Production)

- Automated Scale & Print/Apply Labeling Stations

- Base Pan Whey Removal Stations

- Chambers (Station Qty Varies on Customer Vacuum Profile)

- CIP-able Custom Designed Vacuum

- CIP-able Cyclone Fill Stations (Accept Traditional or Crumbled Product)

- CIP-able Press/Probe Stations (Custom Single To 5 Station Systems with Integrated CIP Tank)

- CIP-able Tip Press Stations

- Custom Sample & Pick-Off Conveyance

- Liner Application Stations

- Metal Detect/Partial Box Fill Reject Pick-off Stations

- Press Stations

- Smooth Pop-Up & Turntable Transfer Designs