Pneumatic Conveyance

Utilizing air can be a cost-effective solution for conveying products from one point to another.

Category: Process

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Pneumatic conveyance is an advanced material handling system that uses air pressure or vacuum to transport bulk materials through pipelines. This technology is widely used in industries such as food processing, pharmaceuticals, chemicals, and manufacturing for its efficiency and flexibility.

- Functionality: Pneumatic conveyance systems move materials like powders, granules, and small solids by creating a controlled air stream within sealed tubes. The material is introduced into the air stream and transported to the desired location.

- Efficiency: These systems offer fast and continuous movement of materials, reducing manual handling and increasing productivity. They are particularly effective for long-distance and complex routing, where traditional conveyors might be impractical.

- Versatility: Pneumatic conveyance can handle a wide range of materials with different properties, including fragile, abrasive, or hazardous substances. It can be adapted for various applications, from feeding processing machines to transferring products between storage silos.

- Hygiene and Safety: The enclosed nature of pneumatic systems minimizes contamination risks and protects the materials from environmental factors. This makes them ideal for handling sensitive products in industries requiring strict hygiene standards.

Pneumatic conveyance systems are crucial for efficient, safe, and flexible material transport in various industrial applications, enhancing overall operational efficiency and maintaining product integrity.

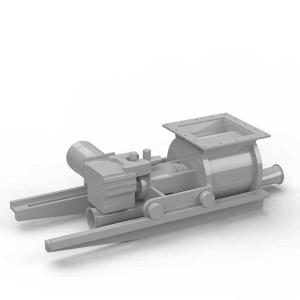

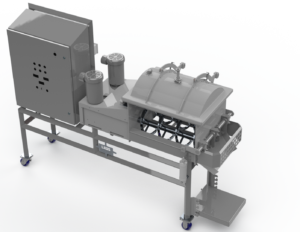

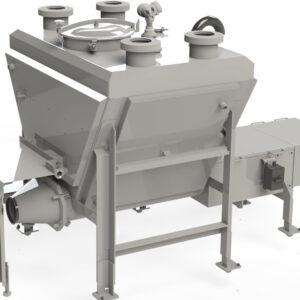

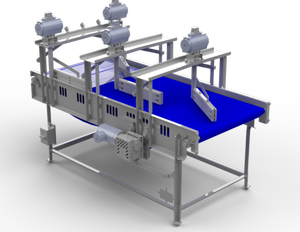

Equipment Gallery

Additional Information

Types

Cheese CurdIQFPowders

Standard Features

Automatically meter your product or ingredients to any point in your process such as cooking or blending

Integrated programmed recipe pages to allow customers to fulfill numerous orders throughout the production day

CIP solutions included within ingredient delivery design

Precise yield accuracy

Integrated programmed recipe pages to allow customers to fulfill numerous orders throughout the production day

CIP solutions included within ingredient delivery design

Precise yield accuracy

Quality

Stainless steel construction

Various sizes available to meet capacity requirements

Manual or PLC controls

Various sizes available to meet capacity requirements

Manual or PLC controls

Automated Solutions

PLC/HMI controls

Automated convey/supply systems for minimal employee interaction

Light curtain and safety protection

Meets NEC, NFPA, and ANSI codes

UL approved

Automated convey/supply systems for minimal employee interaction

Light curtain and safety protection

Meets NEC, NFPA, and ANSI codes

UL approved

Optional Items

Blowers

Rotary airlocks

Divert valves

Crumblers

CIP system

Blower filters

Pigging system

Rotary airlocks

Divert valves

Crumblers

CIP system

Blower filters

Pigging system