Fill Stations

Category: Augured Equipment,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

At Loos Machine & Automation, our Fill Stations are designed to streamline your production process with precision and reliability. Perfectly suited for a variety of industries including food and beverage, our Fill Stations ensure accurate and efficient filling of your products.

Key Features

- Precision Engineering: Our Fill Stations are engineered for accuracy, ensuring every fill is consistent and meets your exact specifications. This precision minimizes waste and maximizes efficiency.

- Versatile Applications: Whether you’re filling bottles, cans, pouches, or other containers, our Fill Stations adapt to your needs. With adjustable settings and customizable options, they handle various container sizes and types with ease.

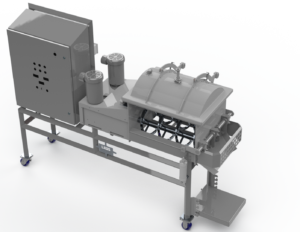

- User-Friendly Interface: Designed with operators in mind, our Fill Stations feature an intuitive control panel that simplifies operation and reduces the learning curve. Quick adjustments and real-time monitoring enhance productivity and ease of use.

- Robust Construction: Built to withstand the demands of high-volume production environments, our Fill Stations are constructed from high-quality materials that ensure durability and long-term performance.

- Hygienic Design: In industries where cleanliness is critical, our Fill Stations are designed for easy cleaning and maintenance. Smooth surfaces and removable parts make sanitation quick and straightforward.

Why Choose Loos Machine & Automation?

- Tailored Solutions: We understand that each operation is unique. Our Fill Stations can be customized to meet your specific needs, from specialized filling mechanisms to integration with existing systems.

- Expert Support: Our team of experts is committed to providing exceptional support throughout the lifecycle of your Fill Station. From installation to ongoing maintenance, we’re here to ensure your equipment runs smoothly.

- Innovation and Quality: At Loos Machine & Automation, we’re dedicated to innovation and quality. Our Fill Stations represent the latest advancements in filling technology, designed to enhance efficiency and performance in your production process.

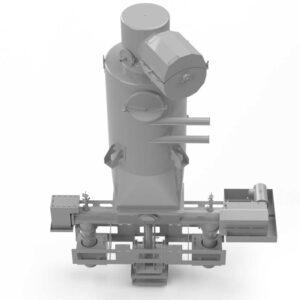

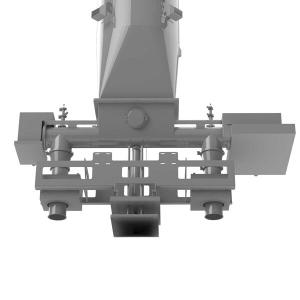

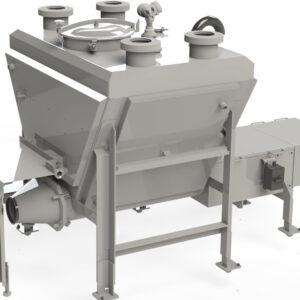

Equipment Gallery

Additional Information

Standard Features

Single, dual and custom line filling stations

Multiple cyclone auger designs available

Exact weight or volumetric

Bulk package down to cup size

Crumbled or traditional curd

Slurries and paste

and more…

Multiple cyclone auger designs available

Exact weight or volumetric

Bulk package down to cup size

Crumbled or traditional curd

Slurries and paste

and more…

Quality

View ports included for easy inspection

CIP-able (variety of spray ball connection points; fixed or removable)

Integrated metal detectors on discharge fill point or in-feed product supply

CIP-able (variety of spray ball connection points; fixed or removable)

Integrated metal detectors on discharge fill point or in-feed product supply

Automated Solutions

Barrel/Block pop-up conveyor designs to maintain system flow

Custom recipe page for cheese filling accuracy

RFID capabilities for tracking product source and variables

Inline labeling systems

Custom recipe page for cheese filling accuracy

RFID capabilities for tracking product source and variables

Inline labeling systems

Optional Items

Integrated Cooling Systems for optimum curd filling temperatures

Weighing systems to maximize product input

Mezzanine & Platform designs for safe accessibility

Funnel extensions for barrel or blocks

Integral formed angles in funnels for blocks (eliminates needs for loose angles)

Metered ingredient application

Weighing systems to maximize product input

Mezzanine & Platform designs for safe accessibility

Funnel extensions for barrel or blocks

Integral formed angles in funnels for blocks (eliminates needs for loose angles)

Metered ingredient application