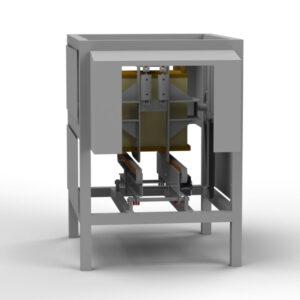

Inverters

Explore how our advanced inverters can elevate your production processes and drive efficiency in your operations. Contact us today to learn more about our inverter solutions and how we can assist you in achieving your automation goals.

Category: Conveyors,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

At Loos Machine & Automation, we understand the critical role that inverters play in optimizing your production line. Our advanced inverter solutions are designed to offer superior control, efficiency, and reliability for a wide range of applications. Whether you need to manage speed, torque, or power, our inverters are engineered to meet your specific needs and enhance the overall performance of your systems.

Key Features:

- Precise Speed Control: Our inverters provide accurate and adjustable speed control, allowing for seamless operation and flexibility in your production processes.

- Energy Efficiency: Designed with energy-saving technologies, our inverters help reduce power consumption and lower operational costs, contributing to a more sustainable production environment.

- Durability and Reliability: Built to withstand demanding industrial environments, our inverters are robust and reliable, ensuring minimal downtime and long-lasting performance.

- User-Friendly Interface: The intuitive controls and interfaces make it easy to set up and operate our inverters, streamlining maintenance and adjustments.

- Versatile Applications: From conveyors and mixers to pumps and fans, our inverters are suitable for a wide array of applications across various industries.

Why Choose Loos Machine & Automation?

- Expertise and Innovation: With years of experience in automation solutions, we bring cutting-edge technology and innovative design to every product we offer.

- Customization Options: We provide tailored solutions to meet the unique requirements of your operations, ensuring optimal performance and integration.

- Comprehensive Support: Our dedicated team offers exceptional customer support, including installation, maintenance, and troubleshooting to ensure your systems run smoothly.

Equipment Gallery

Additional Information

Types

Pneumatic, hydraulic, or motor-driven

Manual or fully automated

Quality

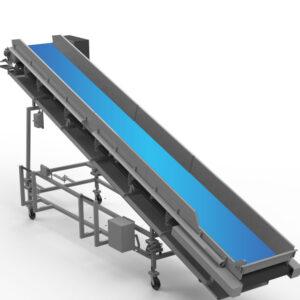

Washdown rated and clean design

Easily accessible maintenance items

Robust design for long-lasting operations

Performance

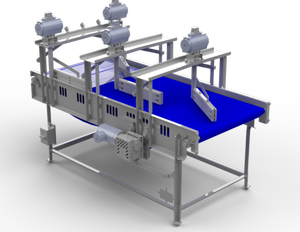

Safer, smoother, and gentler with product

Fully automated

Integrates easily with existing handling systems

Available to handle standard track and cart models

Utilize belts or rollers

Safety guarded

Designed to handle fast throughput systems with consistent control and accuracy

Ease of height adjustment to handle 40’s, 60’s, Tosca, Arena, or Barrel styles and additional product sizes

Automated Solutions

Safety light curtains

Meets NEC, NFPA, and ANSI codes

UL approved

Simple process design

Optional Items

Whey collection station

RFID/Barcode application