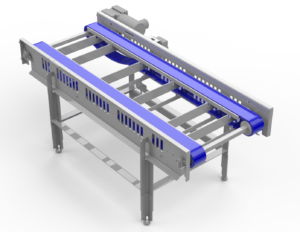

640 Cheese Conveyance

At Loos Machine & Automation, we specialize in delivering innovative and reliable sanitary conveyor systems tailored for the cheese industry. Our systems are designed to enhance efficiency, maintain product integrity, and meet the stringent standards of food safety.

Category: Conveyors

Industry: Cheese/Dairy, Packaging

Equipment Overview

At Loos Machine & Automation, we specialize in delivering innovative and reliable sanitary conveyor systems tailored for the cheese industry. Our systems are designed to enhance efficiency, maintain product integrity, and meet the stringent standards of food safety.

Streamlined Conveyance for Every Stage

Whether handling fresh, IQF, or aged cheese, our conveyance systems are optimized to support smooth operations from production to packaging. Each system is engineered to reduce manual handling, minimize product loss, and ensure consistent quality at every stage of the process.

Customization for Your Unique Needs

Our cheese conveyance systems are fully customizable to meet the unique needs of your operation. With flexible designs that accommodate various types of cheese, our conveyors integrate seamlessly with your existing equipment. We offer solutions for gentle product handling, efficient product transfers, and precise product orientation.

Key Features:

- Food-Grade Construction: Built with stainless steel and other hygienic materials to meet industry sanitation standards.

- Modular Design: Adaptable to different layouts and workflows, our systems grow with your operation.

- Automated Efficiency: Advanced automation options reduce downtime, increase throughput, and provide consistent results.

- Minimal Maintenance: Designed for easy cleaning and maintenance, ensuring minimal disruption to production.

Trusted Expertise in Cheese Handling

For decades, Loos Machine & Automation has been a trusted partner for cheese manufacturers, providing conveyance systems that prioritize reliability and longevity. Our experienced team works closely with you to understand your needs and deliver a solution that optimizes your production line, all while maintaining the highest standards of safety and performance.

Equipment Gallery

Additional Information

Standard Features

Sanitary Design: Open-frame designs allow for easy cleaning and reduced risk of bacterial growth.

Adjustable Speeds: Variable speed controls to manage the flow of product through different stages of production.

Integrated Sensors: Detect product presence and regulate movement, reducing jams and ensuring smooth operations.

Ergonomic Operation: Designed with operator ease in mind, including adjustable heights and safety features to protect employees.

Automated Solutions

Weight-Based Sorting: Automatically sorts products based on weight, ensuring consistency and accuracy.

Automated Infeed/Outfeed Systems: Synchronizes conveyors with other production equipment to streamline operations and reduce manual intervention.

Robotic Palletizing: Automates the stacking and organization of cheese products onto pallets for faster, more efficient shipping.

Vision Systems: Advanced camera systems ensure quality control, detecting irregularities in size, shape, or color and removing defective products from the line.