Conveyors

With decades of experience in the food processing industry, Loos Machine & Automation delivers conveyor systems that enhance productivity, reduce waste, and improve overall operational efficiency. Our team works closely with you to ensure that every conveyor system is designed and built to meet your specific operational goals, while exceeding industry standards for quality and safety.

Category: Conveyors

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

At Loos Machine & Automation, we understand that conveying systems are vital to maintaining smooth, efficient, and hygienic operations in food production. Our range of conveyor solutions is designed to meet the unique demands of handling raw and packaged food products, including cheese, IQF products, bakery items, and more.

Custom-designed to Fit Your Operation

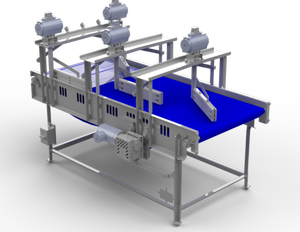

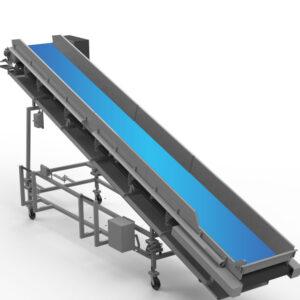

No two operations are the same, which is why we offer fully customizable conveyor systems. From belt conveyors and incline conveyors to spiral and accumulation conveyors, our systems are engineered to seamlessly integrate into your existing processes while ensuring smooth and consistent product flow.

Built for Safety and Hygiene

Our conveyors are crafted with the highest standards of safety and hygiene in mind. Designed for food industry applications, they feature easy-to-clean materials, stainless steel construction, and hygienic designs that minimize product contamination and simplify washdown processes. This ensures that your operation meets stringent industry regulations while optimizing production uptime.

Key Features of Our Conveyors:

- Flexible Designs: Tailored solutions to meet the specific needs of cheese, IQF, and bakery applications.

- Durability and Reliability: Heavy-duty construction ensures long-lasting performance, reducing downtime and maintenance.

- High-Efficiency Systems: Advanced engineering allows for optimized infeed, outfeed, and product handling efficiency.

- Easy Integration: Seamlessly incorporates into your production line with minimal disruption.

- Product Tracking: Accurate tracking capabilities help streamline operations and improve overall workflow.

Equipment Gallery

Additional Information

Performance

Handle throughputs of all shapes and sizes of product from 640 lb. blocks to finished packaged goods

Convey raw or packaged products

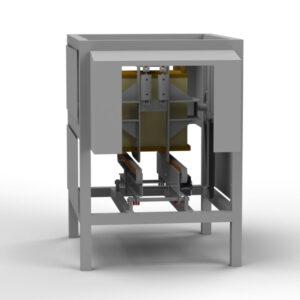

Automated Solutions

Easily accessible located components

Troubleshooting made easy with designed alarmed notifications

Standalone conveyor controls or turn-key system designs

Ingredient delivery (exact weight metering)

Product merging or exact weight sorting

Optional Items

Belt Lifts pneumatic or manual

Spray bars for ease of clean-ability

Systems capable of handling barrel or blocks with minimal transition downtime

Metal detectors

X-Ray

Leak detect

Reject systems

Pneumatic or manual take-ups for easy belt removal

Load cells

Conveyor Types

Maximize floor space with horizontal, incline, decline, corner, and more

Variety of offered transition solutions: pop-ups, turntables, and more

Sanitary design with user clean-ability/wash-down in mind

Safety guarding, pinch point minimization, safe access for cleaning

Horizontal, incline, "z", spiral or radius, screw augers, and more!

Belting Option

Urethane (Variety of colors, temperature ratings, and metal detectable)

Variations of belting styles to assure clean conveyance throughout system

USDA product contact approved belting used

Designed to handle harsh CIP/spray down environments

Other options available