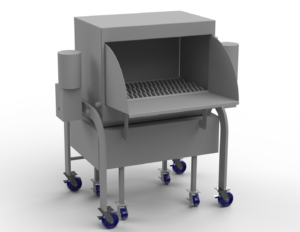

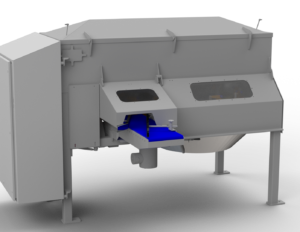

Thermal Controlled Equipment

Our thermal-controlled equipment is designed with both efficiency and reliability in mind, ensuring that your products remain within the optimal temperature range throughout the process.

Category: Augured Equipment,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Pet Food

Equipment Overview

We offer a variety of thermal-controlled systems tailored to meet the unique requirements of your production line. Whether you're managing cold storage for dairy products or maintaining critical heat levels for specific ingredients, our team works with you to design equipment that integrates seamlessly into your operation.

Key Features:

- Precision Temperature Control: Our systems provide accurate and consistent temperature regulation, preventing product degradation or spoilage.

- Energy Efficiency: We prioritize energy-efficient designs, reducing operational costs while maintaining performance.

- Advanced Automation: Seamlessly integrate with your existing control systems, allowing for real-time monitoring and adjustments.

- Durable Construction: Built from high-quality materials like stainless steel, our equipment is designed to withstand the demands of industrial environments.

Applications:

- Dairy products (e.g., cheese storage and handling)

- Frozen food management

- Temperature-sensitive ingredient processing

- Heat treatments and pasteurization processes

Why Choose Loos Machine & Automation?

With years of experience in the industry, we have a deep understanding of the critical role temperature control plays in product safety and quality. Our thermal-controlled equipment is designed to not only meet regulatory standards but also to exceed customer expectations in performance and reliability.

Equipment Gallery

Additional Information

Types

Continuous flow or batch

Water baths

Single & twin screw augers

Conveyance

Quality

Precise thermal management

Performance

Time rates customizable by application

Automated Solutions

Plant integration

PLC/HMI

Optional Items

System or standalone options