Ribbon Blenders & High Shear Mixers

Ribbon Blenders and High Shear Mixers are essential industrial mixing equipment used in various sectors, including food processing, pharmaceuticals, and chemical manufacturing.

Category: Process,Augured Equipment,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Both ribbon blenders and high shear mixers are crucial for achieving consistent and high-quality mixes in various industrial processes, each suited to different types of materials and mixing requirements.

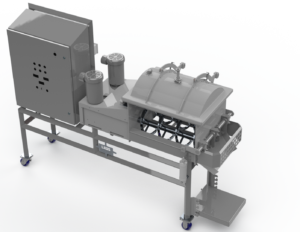

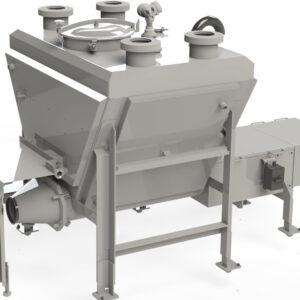

Ribbon Blenders:

- Functionality: Ribbon blenders are designed for gentle and thorough mixing of dry powders, granules, and sometimes pastes. They consist of a U-shaped horizontal trough with a double helix agitator that moves materials in a well-balanced axial and radial flow.

- Efficiency: These blenders ensure uniform blending with minimal heat generation, making them ideal for heat-sensitive materials. Their efficient design allows for large batches to be mixed quickly and consistently.

- Applications: Commonly used for blending spices, flour, pharmaceuticals, chemicals, and other dry ingredients. They are also suitable for light mixing of pastes and slurries.

High Shear Mixers:

- Functionality: High shear mixers use a rotor-stator mechanism to create intense shear forces that rapidly mix, emulsify, homogenize, or disintegrate products. The rotor spins at high speeds, drawing materials through the stator to achieve fine, consistent particle size reduction and dispersion.

- Efficiency: These mixers are highly effective for reducing particle size and ensuring uniform distribution of components, significantly reducing mixing times compared to conventional methods.

- Applications: Ideal for making emulsions, suspensions, and dispersions in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. Common products include salad dressings, creams, ointments, and paints.

Equipment Gallery

Additional Information

Types

Ribbon or paddle mixing blenders

Cheese, meat, and poultry industries

Stainless steel construction with 316 product contact

Various sizes available to accommodate required throughputs

End gate options to easily discharge product

Meets WDA, FDA, and USDA standards

WDA approved sanitary design front and rear shaft seals

Stainless steel bearing design

Cheese, meat, and poultry industries

Stainless steel construction with 316 product contact

Various sizes available to accommodate required throughputs

End gate options to easily discharge product

Meets WDA, FDA, and USDA standards

WDA approved sanitary design front and rear shaft seals

Stainless steel bearing design

Performance

10 lbs. up to 10,000 lbs. capacity

Integrate with single-line systems

Blend and batch systems for required throughputs

Blends for spices and other ingredient additions

Integrate with single-line systems

Blend and batch systems for required throughputs

Blends for spices and other ingredient additions

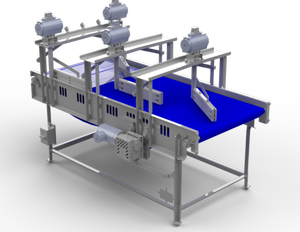

Automated Solutions

PLC/HMI controls

Ingredient delivery

Meets NEC, NFPA, and ANSI codes

UL approved

Vision capabilities (precise knowledge of cut size/weights)

Unlimited recipe integration provided

Safety assessed and category rated

Ingredient delivery

Meets NEC, NFPA, and ANSI codes

UL approved

Vision capabilities (precise knowledge of cut size/weights)

Unlimited recipe integration provided

Safety assessed and category rated

Optional Items

Teflon coating

Single or twin screw for both ribbon or paddle design

CIP-able

Jacketed auger and shell

Load cells for precise recipe management

Multiple ribbon styles for different products and throughput

Variety of automated conveyance solutions between operations

Optional lid slide to allow for low head clearance

Single or twin screw for both ribbon or paddle design

CIP-able

Jacketed auger and shell

Load cells for precise recipe management

Multiple ribbon styles for different products and throughput

Variety of automated conveyance solutions between operations

Optional lid slide to allow for low head clearance