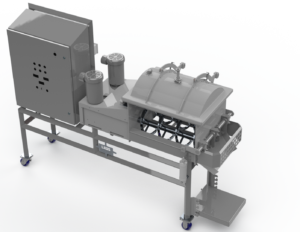

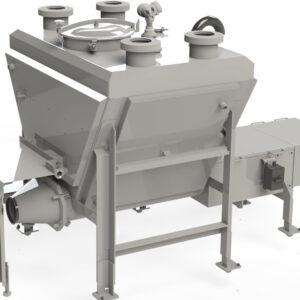

Vacuum Chambers

A tightly sealed vacuum chamber design allows for maximum drawdown pressures.

640 lb. Block and 500 lb. Barrel chamber designs are custom-built to maximize the quality of cheese making. Loos Machine & Automation’s extensive knowledge and experience allow us to work directly with our customers to design custom systems for their specific quality cheese types.

Category: Specialty Equipment

Industry: Cheese/Dairy

Equipment Overview

Our 100+ years of hands-on experience in the cheesemaking industry has provided our Mechanical/Process/ Automation Engineers the exceptional opportunity to deliver the best solutions for optimizing your cheese production requirements.

Loos Machine & Automation provides efficient and reliable automated equipment to vacuum a variety of products. Like all our cheese equipment, our vacuum chambers are designed for seamless integration into your cheese production line with a focus on quality, output, and safety. We also offer a complete assessment of your plant floor plan to ensure you optimize your space usage and production capacity.

Equipment Gallery

Additional Information

Types

Integral press head or available loose press plate on barrel design

Standard Features

Customizable Designs: Tailored to your specific application, ensuring optimal fit and functionality, whether handling barrels, blocks, or other bulk materials.

Air Removal Efficiency: Ensures consistent removal of air from product packaging, minimizing oxidation and enhancing freshness.

User-Friendly Operation: Integrated with intuitive controls and safety features, allowing for easy use while maintaining high standards of hygiene and safety.

Seamless Integration: Designed to work in tandem with existing production lines, minimizing downtime and ensuring smooth transitions from one processing phase to the next.

Quality

Designated lockout/tagout areas with integrated light curtains

Performance

Integrated spray bar designs for ease of cleaning to eliminate confined space hazard

Sized for barrel and block integration

A customizable number of stations and drawdown times to meet the designed throughput (standard options include but not limited to 10, 12, and 16 station offerings)

Built to sustain vacuum pressures without the needs of an accumulation tank

Automated Solutions

Zero operator integration

Easy maintenance and monitoring

Optional Items

Complete process system design and piping installation

Variety of whey collection options