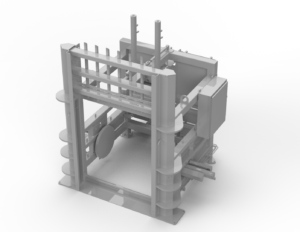

Pre-Breaker

Pre-Breaker systems are designed to handle tough, frozen, or bulk food products that require an initial breakdown before further processing. Our Pre-Breaker efficiently reduces large blocks of product into manageable sizes, ensuring consistent feed into downstream equipment like grinders, cutters, or mixers. Built with durability and precision in mind, it handles a wide range of products, such as frozen meats, cheeses, and other bulk ingredients, making it a crucial step in optimizing your production line.

Category: Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Our Pre-Breaker systems provide unmatched reliability, operational efficiency, and ease of use. By investing in a Loos Pre-Breaker, you ensure that your production process begins with precision and consistency, setting the stage for optimal performance in every subsequent step.

Key Features:

- Heavy-Duty Construction: Built to withstand the rigors of continuous operation, with stainless steel components to ensure durability and hygiene.

- Variable Capacity: Customizable throughput options to meet your production needs, ensuring efficiency at any scale.

- Precision Cutting: Equipped with robust cutting mechanisms for accurate and efficient pre-breaking, minimizing product waste.

- Easy Integration: Seamlessly integrates into existing production lines, reducing downtime and enhancing overall productivity.

- Safety & Sanitation: Designed with operator safety in mind, featuring easy-to-clean components to meet stringent hygiene standards.

Applications:

- Frozen Food Processing: Ideal for breaking down large blocks of frozen food like meats, cheeses, or fruits for further processing.

- Bulk Ingredient Handling: Suitable for handling large volumes of bulk ingredients in preparation for blending or mixing stages.

- Cheese Processing: Perfect for the cheese industry, where large blocks need to be efficiently pre-broken before cubing or slicing.

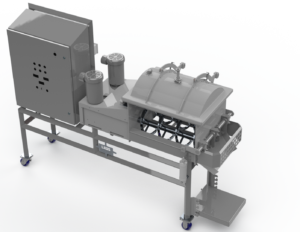

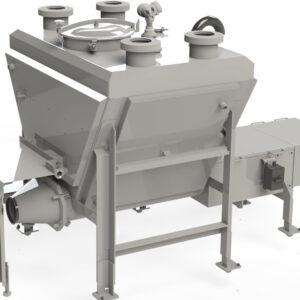

Equipment Gallery

Additional Information

Applications

Bulk Ingredient Handling

Cheese Processing