CIP Skids

Cleaning In Place

Every plant is unique with its own cleaning protocol. We believe the best solution is CIP equipment that matches the process of your plant. We will assist you in developing the most suitable solution.

Category: Process

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Pet Food

Applications:

Equipment Overview

CIP (Clean-in-Place) skids are specialized systems designed for automated cleaning and sanitation of process equipment and piping in industries like food and beverage, dairy, pharmaceuticals, and more. There are several types of CIP skids, each designed to meet specific cleaning requirements. Here are the main types:

1. Single-Tank CIP Skids

- Description: Compact systems with one tank for cleaning solutions. Often used in smaller facilities or for cleaning simple systems.

- Advantages: Lower cost, compact footprint, suitable for systems with low cleaning demands.

- Limitations: Limited ability to handle multiple cleaning cycles simultaneously.

2. Two-Tank CIP Skids

- Description: Systems with separate tanks for cleaning solutions and rinse water.

- Advantages: Improved efficiency as cleaning and rinsing can occur in sequence, reduced water usage.

- Applications: Moderate-scale operations or processes with more stringent cleaning requirements.

3. Three-Tank CIP Skids

- Description: Systems with three dedicated tanks (e.g., one for acid, one for caustic, and one for rinse water).

- Advantages: Greater flexibility for complex cleaning protocols, reduced cleaning cycle time.

- Applications: Large-scale operations or facilities with diverse cleaning requirements.

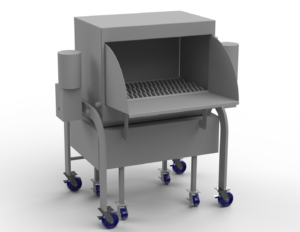

4. Portable CIP Skids

- Description: Mobile units that can be moved between different areas or systems.

- Advantages: Cost-effective for facilities with multiple smaller systems, eliminates the need for permanent installations.

- Applications: Smaller facilities or areas with low frequency of cleaning.

5. Automated CIP Skids

- Description: Fully automated systems with programmable controls for cleaning parameters like temperature, flow rate, and chemical concentration.

- Advantages: Consistent cleaning results, minimal manual intervention, integration with process control systems.

- Applications: High-demand industries such as pharmaceuticals, dairy, and large-scale food processing.

6. Custom CIP Skids

- Description: Designed and built to meet specific requirements, such as unique piping layouts, special cleaning agents, or space constraints.

- Advantages: Tailored to exact needs, ensuring optimal performance.

- Applications: Facilities with unique processes or cleaning challenges.

7. Modular CIP Skids

- Description: Pre-engineered systems with modular components that can be easily expanded or reconfigured.

- Advantages: Scalable, adaptable to future needs.

- Applications: Facilities expecting growth or changes in their cleaning requirements.

8. Hybrid CIP Skids

- Description: Systems combining manual and automated features.

- Advantages: Flexibility, cost-effectiveness for certain operations.

- Applications: Facilities with a mix of simple and complex cleaning needs.

9. Single-Use CIP Skids

- Description: Designed for single-use cleaning in sensitive applications where cross-contamination is a concern.

- Advantages: Eliminates contamination risks, no cleaning solution recycling.

- Applications: Pharmaceuticals or biotech processes.

Each type of CIP skid is suited to specific cleaning tasks and operational scales. Choosing the right one depends on factors like the size of the facility, complexity of the cleaning process, regulatory requirements, and budget.

Equipment Gallery

Additional Information

Types

Dedicated to single machine or full plant cleaning

Standard Features

Automated Solutions

Fully automated operation

Stand alone unit

Fully integrated Unit