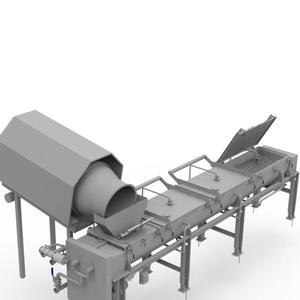

Auger Conveyance Systems

Improve product flow and eliminate waste for a variety of applications by using auger conveying methods.

Conveying rates, angles, and distances are all designed around product characteristics for your custom solution.

Category: Conveyors,Augured Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Pet Food

Equipment Overview

Loos Machine & Automation’s auger conveyance systems provide reliable and efficient solutions for transporting bulk materials in a wide range of industries. Our systems are designed for precision, durability, and easy integration into your existing production line, offering unparalleled performance in even the most demanding environments.

Efficient Conveyance for Bulk Materials

Our auger conveyance systems excel at moving powders, granules, and semi-solid materials with precision and minimal product degradation. Whether you’re handling food products like cheese powders or industrial materials, our augers ensure smooth, continuous transport while maintaining product integrity.

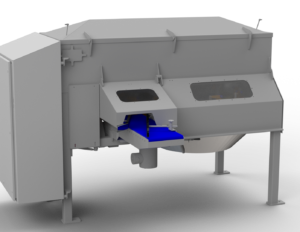

Types of Auger Conveyance Systems:

- Flexible Screw Conveyors: Versatile and ideal for moving materials through complex layouts, handling various bulk materials with ease.

- Horizontal Auger Conveyors: Designed for efficient transport of bulk materials in a horizontal direction, perfect for integration into existing production lines.

- Inclined Auger Conveyors: Designed for elevating materials from one process to another, ensuring smooth material flow between levels.

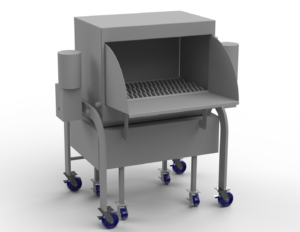

- Hopper Auger Systems: Combine augers with hoppers for controlled, consistent material feed, perfect for applications requiring measured dispensing.

Equipment Gallery

Additional Information

Types

Vertical

Spiral

Stationary/portable

Standard Features

Customizable Lengths and Diameters: Auger systems are available in various configurations to suit your specific material and production needs.

Sealed Systems: Ensures no contamination or material loss, maintaining product quality throughout the transport process.

Low Maintenance Design: Minimal wear components and easy-to-access parts for hassle-free cleaning and maintenance.

Adjustable Speeds: Control material flow rates to match production requirements and ensure smooth operation.

Performance

Automated Solutions

PLC/HMI controls

Meets NEC, NFPA, and ANSI codes

UL approved

Optional Items

Hoppers

Metal detection

Vibration sensors