Blending & Mixing

At Loos Machine & Automation, we understand that no two blending or mixing processes are the same. Our systems are fully customizable to meet the specific needs of your operation, from the type of materials being mixed to the scale of your production. Whether you need a compact solution for a small operation or a high-capacity system for large-scale production, we deliver equipment tailored to your requirements and are available in sizes ranging from 100 lbs. to 10,000 lbs.

Need to provide exact weight blends for a variety of recipes? Let us help you with our reliable automated blending systems!

Category: Process,Augured Equipment,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Loos Machine & Automation’s Blending and Mixing Systems are engineered to deliver precise, consistent results across a wide range of materials and industries. From food products to industrial applications, our systems ensure uniform mixing, reduced processing times, and optimal performance for even the most demanding environments.

Precision in Every Blend

Our blending and mixing solutions are designed for efficiency and accuracy. Whether you’re handling powders, liquids, granules, or semi-solids, our systems ensure even distribution and consistent results, reducing product variation and ensuring quality.

Types of Blending & Mixing Systems:

- Ribbon Blenders: Ideal for powders and granules, offering gentle and thorough mixing for homogeneous blends.

- Paddle Mixers: Designed for handling larger particles and delicate materials without causing damage or degradation.

- Vertical Mixers: Efficiently handle both dry and wet materials, ensuring complete and even mixing.

- Tumble Blenders: Perfect for high-shear applications, ensuring uniform blends in a shorter processing time.

Standard Features:

- Food-Grade Materials: Built from stainless steel and other hygienic components to meet stringent food safety requirements.

- Precise Mixing Controls: Variable speed options and programmable controls allow for customized mixing times and intensities.

- Seamless Integration: Easily integrates with other upstream or downstream equipment to enhance overall production efficiency.

- Easy Maintenance: Designed for minimal downtime, with easy access for cleaning and maintenance, keeping your operation running smoothly.

- Batch or Continuous Operation: Configurable for both batch mixing and continuous production depending on your workflow needs.

Automated Solutions:

- Automated Ingredient Feeding: Integrates with automated systems for precise ingredient dosing, ensuring consistent mixtures every time.

- Automated Discharge Systems: Streamlines the unloading process, reducing manual handling and speeding up production times.

- In-Line Monitoring: Integrated sensors monitor mixture consistency and automatically adjust settings to ensure uniformity across batches.

- Data Integration: Track production data in real time to optimize blending performance, ensuring consistent quality and reduced waste.

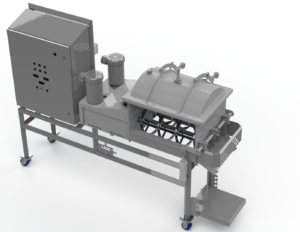

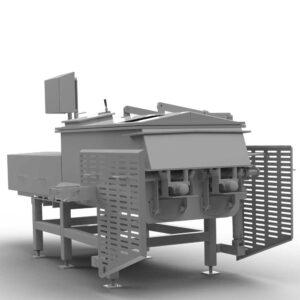

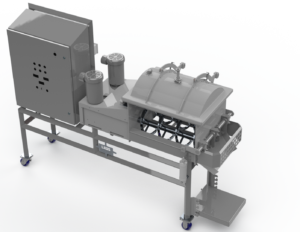

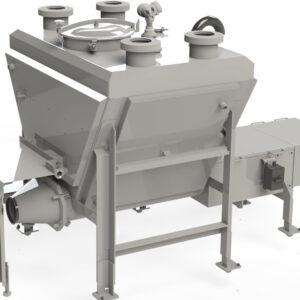

Equipment Gallery

Additional Information

Performance

Integrate with single-line systems

Blend and batch systems for required throughputs

Blends for spices and other ingredient additions

Automated Solutions

Ingredient delivery

Meets NEC, NFPA, and ANSI codes

UL approved

Vision capabilities (precise knowledge of cut size/weights)

Unlimited recipe integration provided

Safety assessed and category rated

Optional Items

Single or twin screw for both ribbon or paddle design

CIP-able

Jacketed auger and shell

Load cells for precise recipe management

Multiple ribbon styles for different products and throughput

Variety of automated conveyance solutions between operations

Optional lid slide to allow for low head clearance

Types, Styles and Features

Cheese, meat, and poultry industries

Stainless steel construction with 316 product contact

Various sizes available to accommodate required throughputs

End gate options to easily discharge product

Meets WDA, FDA, and USDA standards

WDA approved sanitary design front and rear shaft seals

Stainless steel bearing design