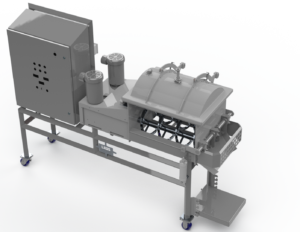

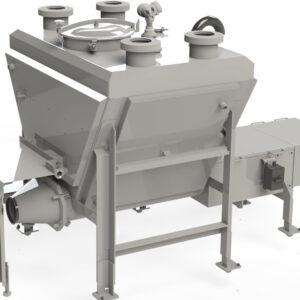

Auto Doughball Placer

Our Auto Doughball Placer is fully customizable to fit your production line layout and workflow. Whether you need single or multi-lane placement, integration with existing equipment, or specific adjustments to handle unique dough formulations, Loos Machine & Automation works with you to develop the ideal solution.

Category: Specialty Equipment

Industry: Pizza/Bread

Equipment Overview

Loos Machine & Automation’s Auto Doughball Placer is engineered to streamline and automate the dough handling process, ensuring precise placement and consistency for high-volume production lines. Whether you’re producing pizza dough, bread, or other dough-based products, our system delivers unmatched efficiency and accuracy.

Precision Doughball Placement

Our Auto Doughball Placer is designed to handle various dough sizes and weights with gentle, consistent precision. This system reduces manual labor, enhances production speed, and ensures that every doughball is placed accurately, minimizing product waste and maximizing output.

Key Features:

- High-Speed Operation: Capable of handling large volumes of doughballs at rapid speeds, improving throughput and meeting demanding production targets.

- Consistent Placement: Ensures uniform placement of doughballs on trays, conveyors, or baking sheets, maintaining product consistency across batches.

- Adjustable Settings: Easily adjust placement patterns, dough sizes, and speeds to meet the specific needs of your product line.

- Food-Grade Materials: Constructed from stainless steel and other hygienic materials, ensuring compliance with food safety standards and easy cleaning.

- Gentle Handling: Our system is designed to handle dough gently to maintain its structure and prevent deformation.

Equipment Gallery

Additional Information

Standard Features

Check-weigh system ensures quality

Complete safety guarding

Can accommodate any desired product rate

Automated Solutions

Vision-Guided Placement: Optional vision systems ensure doughballs are placed with pinpoint accuracy, even on moving trays or conveyors.

Data-Driven Efficiency: Integrated sensors and data tracking optimize performance by monitoring throughput, placement accuracy, and system efficiency in real-time.

Recipe Management: Programmable controls allow for quick changeovers between different doughball sizes or recipes, maximizing production flexibility.

Applications

Raw or packaged products