De-Packing Equipment

Increase safety and reduce labor for a variety of products with our de-packaging systems.

Category: Conveyors,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

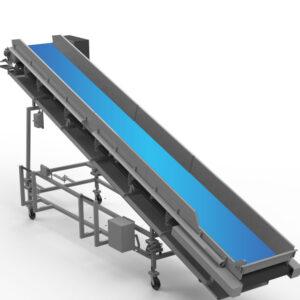

Our de-packing equipment is designed to streamline your production process by automating the unpacking of various materials, from barrels and pallets to boxes. Whether you need to de-pack raw materials or finished goods, our solutions ensure that your products are handled with care and precision, reducing labor costs and increasing overall efficiency.

Barrel Clamp and Hoist System with Auto Inverter

The Barrel Clamp and Hoist System with Auto Inverter is engineered for the safe and efficient handling of large barrels. This system automates the process of lifting, inverting, and de-packing barrels, ensuring that your materials are quickly and safely transferred to the next stage of production.

- Automated Mechanical Guidance : Reduces manual intervention, minimizing the risk of injury and labor costs.

- Auto Inverter : Streamlines the de-packing process by automatically inverting barrels to empty contents efficiently.

- Enhanced Safety : Designed with safety features to protect both operators and products during handling.

De-Lining/Cutting Applications

For products that require de-lining or cutting before processing, our equipment offers precise and reliable solutions. These systems are ideal for removing liners, cutting open packaging, and preparing products for further processing.

- Precision Cutting : Ensures clean and accurate cuts, reducing waste and product damage.

- Automated De-Lining : Removes liners efficiently, preparing products for the next stage with minimal manual effort.

- Versatile Applications : Suitable for a wide range of packaging types and materials.

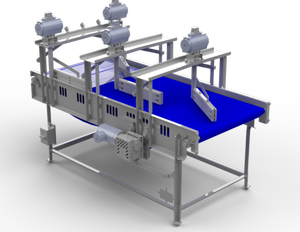

De-Palletizer

Our De-Palletizer system automates the process of unloading products from pallets, ensuring smooth and efficient transfer to the production line. This system is designed to handle various product sizes and weights, making it a versatile addition to your operations.

- Fast and Efficient : Maximizes throughput by quickly and accurately de-palletizing products.

- Automated Handling : Reduces the need for manual labor, increasing safety and efficiency.

- Flexible Configuration : Adaptable to different pallet sizes and product types.

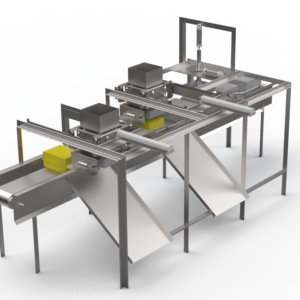

De-Boxing

The De-Boxing system is tailored for the efficient removal of products from boxes, minimizing manual handling and reducing the risk of product damage. This system is ideal for industries that require high-speed de-boxing to maintain production efficiency.

- High-Speed Operation : Increases productivity by de-boxing products quickly and accurately.

- Product Integrity : Ensures products are handled gently to prevent damage.

- Automated Process : Reduces labor costs and increases consistency across the production line.

Equipment Gallery

Additional Information

Types

De-lining/cutting applications

De-palletize

De-boxing

Standard Features

De-package and stage product maximizing system throughputs

Infeed/outfeed efficiency

Product tracking

Quality

Integrate with new or existing systems

Automated Solutions

Tracking and scanning options

PLC/HMI Controls

Customizable

UL approved

Robotic assistance

Optional Items

Semi-automatic

Fully automatic